Restore Mobile Devices with Ultrasonic Cleaners

The consumer electronics market size was valued at over USD 1 trillion in 2020 and is estimated to grow at a CAGR of more than 8% from 2021 to 2027, according to a Global Market Insights report. It defines electronics as computers, laptops, mobile devices, smart wearables, TVs, appliances, etc. Ultrasonic electronics cleaners contribute to reliable operation from manufacturing through servicing these products.

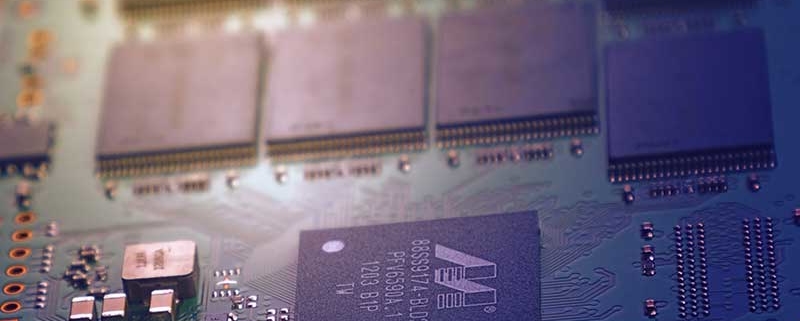

Common to most if not all consumer electronics products is the ubiquitous printed circuit board or PCB. That’s why PCB fabricators or those who sell or service equipment incorporating PCBs and other delicate electronic components include an ultrasonic electronics cleaner in their equipment inventory.

Using Ultrasonic Electronics Cleaners

Unlike potentially damaging mechanical cleaning PCBs and other delicate electronic components by using brushes and environmentally unfriendly solvents, ultrasonic electronics cleaners use the power of ultrasonic cavitation. This method quickly, thoroughly and safely remove contaminants, whether from manufacturing or prolonged use, from all surfaces immersed in a biodegradable ultrasonic cleaning solution.

If you are not that familiar with this method of cleaning please check this post describing how ultrasonic cleaners work.

Elma offers a number of ultrasonic cleaners that are ideal for fabricators and service providers to clean and service PCBs and other precision electronic components. (A real-life example is provided later in this post.) Here are points to keep in mind when you are shopping for your ultrasonic electronics cleaner:

- Select an ultrasonic electronics cleaner large enough to accommodate parts being cleaned (see above link on how they work for more details).

- Select an ultrasonic cleaner with a “Sweep” function to prevent potentially damaging harmonic vibrations along with unwanted “dead” and “hot spots”.

- Follow cleaning solution manufacturers’ instructions concerning diluting the concentrate, the correct cleaning temperature and estimates of cleaning time. More on cleaning solutions later in this post.

- Fill the tank half way with water, add the correct amount of cleaning solution formulation for a full tank and continue adding water to the fill line.

- Turn on the unit without a load to mix and degas the solution to remove air trapped in the liquid, which slows down the cleaning process. Some units are equipped with a Degas mode to speed the process.

- Place the electronic parts in a basket or rack in such a way that they do not contact each other. When ready lower them into the solution.

- At the end of the cycle remove and inspect. When satisfied rinse the components with de-ionized water to thoroughly remove cleaning solution residues and allow them to dry. Large capacity manufacturers or service providers may employ electric dryers for this process.

A Case Study on Ultrasonic Electronic Cleaning

Here we share information on cleaning PCBs with ultrasonic cavitation as developed by IDC Technologies. While it relates to cleaning hand-assembled circuit boards made with a water-soluble flux its value lies in the fact that the customer developed its best way to clean PCBs through experimentation.

The company uses the dual-frequency, heater-equipped Elmasonic P180H model. It was selected because the P series offers adjustable ultrasonic power that can be set from 30% to 100% of the P180H unit’s 330-watt effective power. It also allows the operator to select either 37 kHz or the less aggressive 80 kHz ultrasonic frequency.

The P line provides the critical Sweep mode to prevent harmonic vibrations that could damage delicate PCB electronics, and a Degas mode to drive off cavitation-inhibiting entrapped air.

IDC’s PCB Cleaning Steps

Boards are carefully positioned in the cleaning basket so they do not contact each other. The ultrasonic cleaner is readied by turning on the generators which activate the Sweep mode, setting the thermostat to 30⁰C (86⁰F) and the power to 30%.

Set and actual values are displayed on the control panel. When all is ready the basket is immersed in the solution and the timer set for 7 minutes.

The 7-minute cleaning cycle may vary depending on the number of boards cleaned and their condition.

At the end of the cycle the basket is removed and the boards are rinsed using deionized water then air-dried under a fan.

While the process in general is excellent for PCB cleaning it cannot be used when they contain sealed board-mounted relays.

Selecting and Using an Ultrasonic Electronics Cleaner for Mobile Devices

For cleaning mobile devices you should consider the ¾ gallon Elma Plus 30H or 1½ gallon E Plus 60H ultrasonic cleaners available from Elmaultrasonic.

The Elma E Plus line is especially ideal for the job because units are equipped with an automatic Sweep mode that is very important to prevent damage to sensitive PCB assemblies, a heater to further improve the ultrasonic cleaning process, and a timer.

A recommended cleaning solution is elma tec clean A1 as described on our cleaning solutions page. It should be diluted 1:20 with water. As suggested earlier in this post fresh solutions should be mixed and degassed. For the E Plus units you accomplish this by activating the Pulse mode for a short period of time.

Need More Info on Cleaning Electronics?

Please contact our scientists for recommendations based on your specific requirements. Simply give us a call.