Sonication Baths for Sample Preparation

Sonication baths are used to prepare samples in research and development, transforming analytes into measurable form. This can involve complex procedures that in many cases must avoid chemical degradation from heat or mechanically induced damage.

For example, a sonicator may be used to extract an active pharmaceutical ingredient (API) from its carrier, or excipient, prior to conducting content uniformity and potency assay tests. Many USP monographs recommend using an ultrasonic bath to dissolve samples prior to analysis.

This post describes sonication bath equipment options for sample prep, examples of where the process is used, and provides suggested operating procedures.

Technical Journals Cite Roles of Sonication Baths in Sample Prep

Here are examples of ultrasound and ultrasonic processing being employed across several disciplines:

- Optimization of Pharmaceutical Processes, Chapter 8: “A growing need for developing novel technologies for obtaining better quality products with enhanced process efficiency has created promise for application of ultrasound in the area of food and pharmaceutical processing.”

- Sample Preparation of Pharmaceutical Dosage Forms, Chapter 2, discussing agitation and particle size reduction, notes “techniques include grinding, milling or blending, homogenization, and sonication.”

- Optimization of Pharmaceutical Processes, Chapter 2 notes “that application of ultrasound under the desired conditions can give advantages such as greater control over particle size, enhanced solubility of drugs, controlled crystallization, and production of nanomaterials.”

Sonicator baths also find application in other industries.

- The abstract for Applications of ultrasound in processing of liquid foods: A review states “Ultrasonic processing of a variety of liquids, drinks and beverages has generated much interest with published literature papers increasing within this area in recent years. Benefits include enhanced emulsification with improved homogenization and fat globule size reduction being recorded.”

- Current trends in sample preparation for cosmetic analysis notes “Sample preparation for cosmetic analysis is a crucial step as the complex matrices may seriously interfere with the determination of target analytes.” Ultrasonic-assisted extraction is listed among developments in sample preparation techniques.

Other Applications for Sonicator Baths

- An alternative to mechanical breakup of samples to avoid heat damage and cross-contamination

- Prepare difficult-to-dissolve samples for HPLC analysis

- Extract active pharmaceutical ingredients from excipients

- Degas molasses to measure sugar content to meet ICUMSA standards

- Prepare samples for potency analysis

- Degas shampoo prior to viscosity measurement

- Dissolution and homogenization of cosmetic products

- Extract salts from paper surfaces for analysis

- Deagglomerize soil and clay for particle size analysis

- Extract drugs from hair samples

- Prepare samples for toxicology procedures and tissue biopsies

- Extract contaminants from soils and construction materials prior to analysis

- Extract residues from food and cosmetic samples for determination by LC-MS

- Emulsify food samples

How a Sonicator Bath Performs Sample Prep

Ultrasonic is defined as sound above the range of human hearing (nominally 20,000 cycles per second or 20 kHz). In sample prep applications it is used to create high-frequency energy in liquids.

Glass vessels containing samples and solvents are positioned in a sonicator bath, its tank containing water and a surfactant.

When activated, the unit’s generators excite transducers bonded to the bottom of the tank to vibrate at ultrasonic frequencies. The tank bottom serves as a membrane; its vibration creates sound waves in the liquid. The sound waves pass through the walls of glass beakers and flasks positioned in the tank. These sound waves produce millions of microscopic vacuum bubbles in the liquid. This is termed cavitation.

The cavitation bubbles are unstable and implode with violent force. The energy released by the implosions agitates the contents of the glass vessels, rapidly dispersing, mixing, or dissolving the samples.

Ultrasonic Bath Equipment for Sample Prep

R&D and QC personnel responsible for sample preparation have a variety of requirements and procedures to follow when performing their activities. In QC operations ultrasonic cleaner models supporting standardized, repetitive procedures improve efficiency and reproducibility. In R&D applications adjustable models that enable customized procedures are advantageous.

Here are examples:

Small Sample Preparation

The 3.9 gallon Elmasonic Select 150 is ideally suited for USP methods that specify a sonicator bath for sample preparation involving a large number of small samples.

It consistently gives reproducible sample prep results across a wide range of applications including solubilizing, dissolving, digesting, dispersing, emulsifying, homogenizing and mixing.

The efficiency of the Elmasonic Select 150 for sample preparation is due to a combination of these features:

- A relatively large surface area (19.9 inches x 11.8 inches) but a depth of only 3.9 inches*

- Program up to 4 commonly used procedures to save setup time

- 37 kHz ultrasonic frequency

- 300 watts effective ultrasonic power

- A degas mode removes trapped air from solvents

- A pulse mode provides brief increases in ultrasonic power for mixing and sample prep

- A brilliant digital display of operating parameters and status

*The result is a significantly higher power per unit volume in this model. This means the process can be completed before heat buildup, a natural result of ultrasonic energy, that can cause sample degradation in certain instances.

Baths for Larger Samples

Units are available for personnel working with larger samples requiring deeper immersion in the sonicator solution, or samples that are more difficult to process.

The 7.4 gallon Elmasonic Select 300 has the same operating features and benefits, tank width and length, but a 7.9 inch depth. The recommended 4.5-inch deep basket accommodates larger flasks.

The Select line is offered in 11 tank sizes from 0.75 to 24 gallons, all of which feature programmable operations enabling technicians to call up a program and repeat the same process as needed. This is important in quality control labs doing repetitive sample prep.

Baths for Delicate-to-Difficult Samples

When operated for sample preparation, the adjustable power feature of the dual frequency Elmasonic P line makes it suitable for

- preparing very delicate samples (e.g. dispersion of liposomes without disrupting their structure)

- preparing samples that require very high intensity mixing such as dispersion of nanoparticles that tend to aggregate and dissolving nearly insoluble samples

- processing particularly difficult samples with the user-activated pulse mode

Operators select 37 or 80 kHz for vigorous or gentle processing, or automatically alternate between the two, and set the adjustable power intensity from gentle to strong.

These features, in addition to having the highest average and peak power of any bath sonicator on the market, make the Elmasonic P line ideal for R&D labs carrying out a wide variety of mixing operations, both gentle and strong. The tank’s convenient digital display continuously shows set and current operating parameters with no scrolling.

Ultrasound Sample Prep Preparations

First: Assemble the right equipment.

“The right tools make the job go smoother” applies appropriately when performing sample preparation exercises in the laboratory. As an assist to researchers, Tovatech offers a comprehensive selection of accessories for their Elmasonic ultrasonic bath offerings.

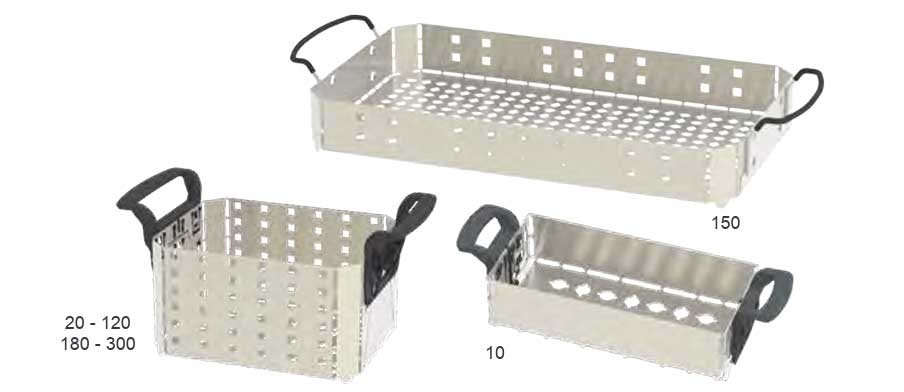

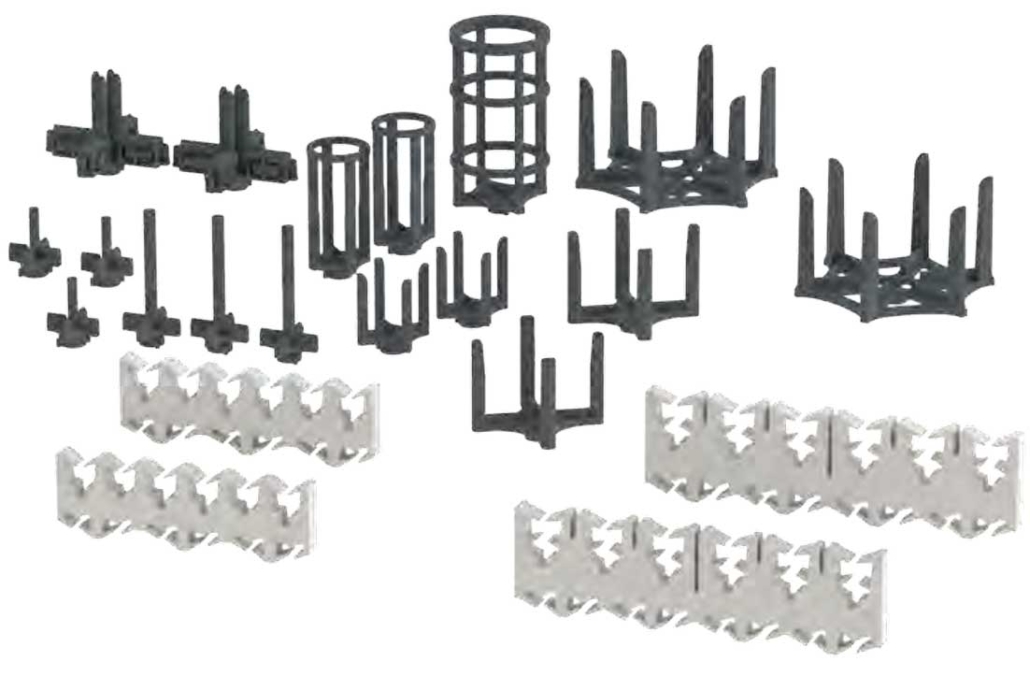

Many of these “tools” are based on Elma Ultrasonic’s newly designed modular basket system, and are designed to accommodate bottom-mounted vials, flasks and similar sample containers.

Unlike mesh and solid-wall baskets, modular baskets can be subdivided horizontally and vertically – “walls and floors” in apartment house terminology. This enables researchers to simultaneously conduct, in different “apartments,” a variety of analyses requiring different sample containers and solvents.

Silicon holders snapped into the modular baskets support “apartment” walls and floors.

Pin sets mount and support racks and clamps holding flasks, vials, test tubes, centrifuge tubes, beakers, and similar sample containers in the bath.

Cooling coils maintain bath temperature at a safe level to avoid heat-related sample degradation.

Vented mute boxes reduce operation noise by up to 85%.

A listing of accessories based on Elma Ultrasonic’s modular basket system, is presented in the comprehensive product information catalog.

Offerings include a “Starter Set” to help you develop “the right tools” to improve the efficiency of your procedures.

If you have questions or concerns on accessories that can be of value supporting your sample analysis, please contact us.

Then: Establish your procedures.

The bath should be filled with water and a surfactant to promote cavitation. This solution should be degassed before positioning your samples in the bath. The degassing process removes trapped air that reduces the efficiency of cavitation.

The Elmasonic Select and P series have a degas mode that quickly accomplishes the process.

- Prepare samples in accordance with established operating procedures and place them in containers along with the recommended solvent.

- Set bath operating parameters on the unit’s control panel.

- Position the containers, using the appropriate accessories, in the unit’s basket.

- Activate the unit and lower the basket into the bath solution.

Ultrasonic waves penetrate the walls of the flasks causing cavitation to occur in the flask solution as well. Bubbles implode on contact with samples causing them to disperse and dissolve.

Summary and For Further Questions

Sample preparation is an exacting science in the pharmaceutical, food, cosmetic, beverage and other industries. A sonicator bath is an ideal tool for preparing samples for analysis.

For answers to questions or additional information on equipment and accessory options for your sample prep operations, contact the scientists at Tovatech, Elma’s exclusive master distributor for North America. We provide unbiased help in specifying and using the correct equipment to prepare samples for your assays.